Services

What is Calibration?

Calibration is essential the comparison under specified conditions with a higher standard, which is traceable to a national or International standard.

read moreNeed for Calibration

Measurement is crucial in science, Industry and Commerce.Measurement is also performed in our daily life.

read more...Calibration Laboratory

Internet this the first of true generator on the Internet. It uses a dictionary of over 200 Latin words, combined with handful of model sentence.

Calibration is essential comparison under specified conditions with a higher standard, which is traceable to a national or International standard.

Calibration fulfills two objectives

It determines accuracy of the measured data

It provides traceability to the measurement.

Measurement is crucial in science, industry and comerce. Measurement is also performed in our daily life.

Like Measurements for health care, such as measuring body temp.with clinical thermometer, checking blood pressure & Many other tests.

checking the time of the day, Billing of power consumption through an energy meter, etc.

Accuracy & Reliability of all such measurements would be doubtful if the instruments used were not calibrated. calibration ensures that a measuring instrument displays an accurate & Reliable value of the quantity being measured.

Thus calibration is essentail in any measurement process.

Periodic calibration of instruments, gauges helps to produce reliable inspection / test results.

Periodic calibration lowers the repair costs.

It prevents delays in testing

Maintains productivity.

Calibartion aims to economize time, labour & Other resources in any production by means of accurate verification.

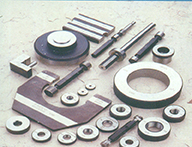

Unik Gauges & Tools manufacturer of precision gauges is involved in gauges manufacturing since 1996 witha commitement to fulfill its customer requirements by providing good quality gauges at competitive prices.

We are serving a host of customers across the country & Abroad by offering them a superior range of gauges & have maintained cordial business relationship with our customers.

To meet the customer requirements & to upgrade our manufacturing product, calibration facility is established in accordance with ISO/IEC 9001 : 2015

Our calibration Laboratory has been accredited by National Acceditation Board for Testing & Calibration Laboratories (NABL) Department of science & technology, Government of India, New Delhi in the field of mechanical parameters provided with best CMC (Calibration Measurement Capability).

Our calibration reports are acceptable to all ISO, TS certifying bodies, National & International Organization, Public & Govt. Sectors etc.

The Customer is the primary focus of our management & our goal is to provide the customer with efficient & Quality service.

We have calibration setup with following master equipments.

Universal Length Measuring Machine (LMM 300T)

- Measuring Capacity 0-300 mm least count - 0.0001 mm

Measurement Uncertainty (0.5 + L/300) um Where L is in mm - Used for calibration of Taper Thread Ring Gauges (NPT, BSPT etc.), Plain Taper Ring gauges, plain Taper Plug Gauges, Plain Ring Gauges, Master setting ring gauges, Thread Ring Gauges, thread plug gauges.

Floating Carriage Diameter Measuring Machine

- Measuring range 0-200 mm least count - 0.0001 mm Accuracy - 2.5 um

- Used for calibration of Thread plug gauges and taper thread plug gauges (NPT, BSPT etc.)

Electronic Dial calibration tester (With Sylvac Probe)

- Measuring range 0-25 mm Least Count - 0.0001 mm Accuracy - 2.5 um

- Used for calibration of plunger Dial Gauges, Lever Dial Gauges & Bore Gauges.

Electronic Comparator with Stand

- Measuring 0 -200 mm Least Count - 0.0001 mm Accuracy - 0.9 um.

- Used for the calibration of plain gauges, cylindrical setting masters and micrometer setting standards.

Carbide Slip Gauges set (M10) ) Grade used for calibration of Micrometers

Carbide slip Gauges set (M88) 0 Grade Used for calibration of snap gauges, plug gauges etc.

Caliper Checker 0 - 600 mm

- Used for calibration of vernier caliper, vernier height gauges, electronic height gauges. UGTCL Schedules services around your companie's work flow intending to minimize any impact on your firms production continuity. we will provide recall letter listing equipment, gauges & calibration due dates one month prior to the due dates of your firm's instruments & gauges, providing assistance to our customers in accurate & timely scheduling of equipment & gauges.